-

What Is a Flatbed Semi-Trailer and How Does It Work? Definition and Structural Design A Flatbed Semi-Trailer is a type of transport vehicle commonly used for the transportation of large, heavy, and ir...

READ MORE -

From massive construction projects to cross-country logistics, the role of reliable hauling equipment is more vital than ever. One vehicle that stands out in this arena is the Heavy Duty Trailer, a po...

READ MORE -

When it comes to moving large loads or transporting heavy equipment, a Heavy Duty Trailer is an indispensable tool in the transportation industry. Whether for construction, mining, or long-haul shippi...

READ MORE -

What is a flatbed semi-trailer, and how does it differ from a regular trailer? A flatbed semi-trailer is a simple, open-platform vehicle. Its key feature is the lack of fixed side panels and a roof, r...

READ MORE

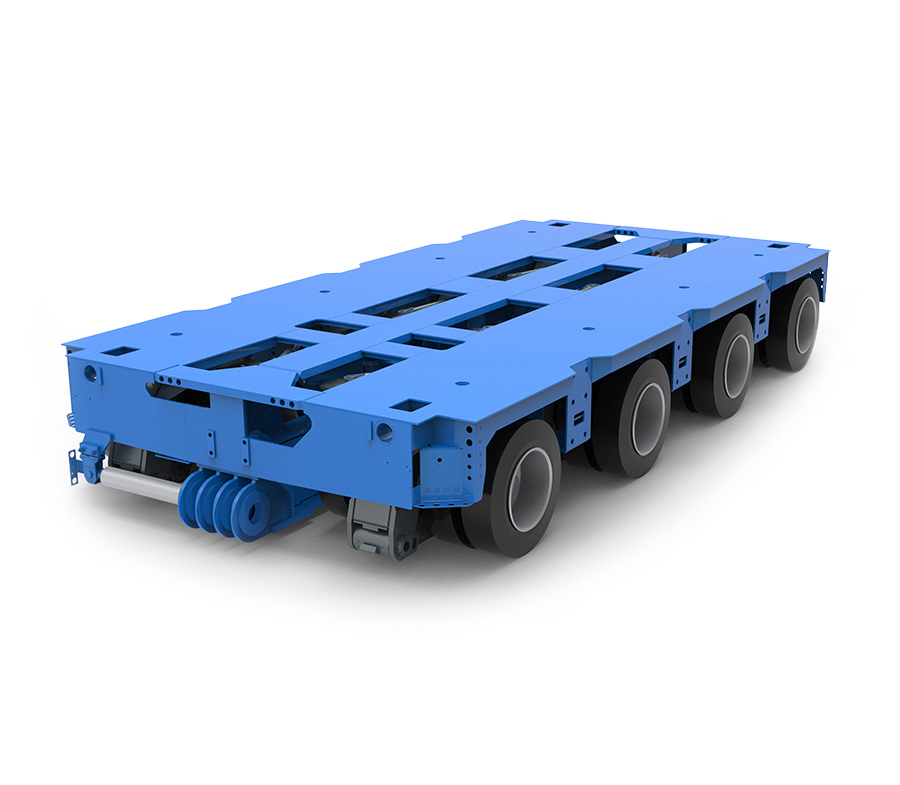

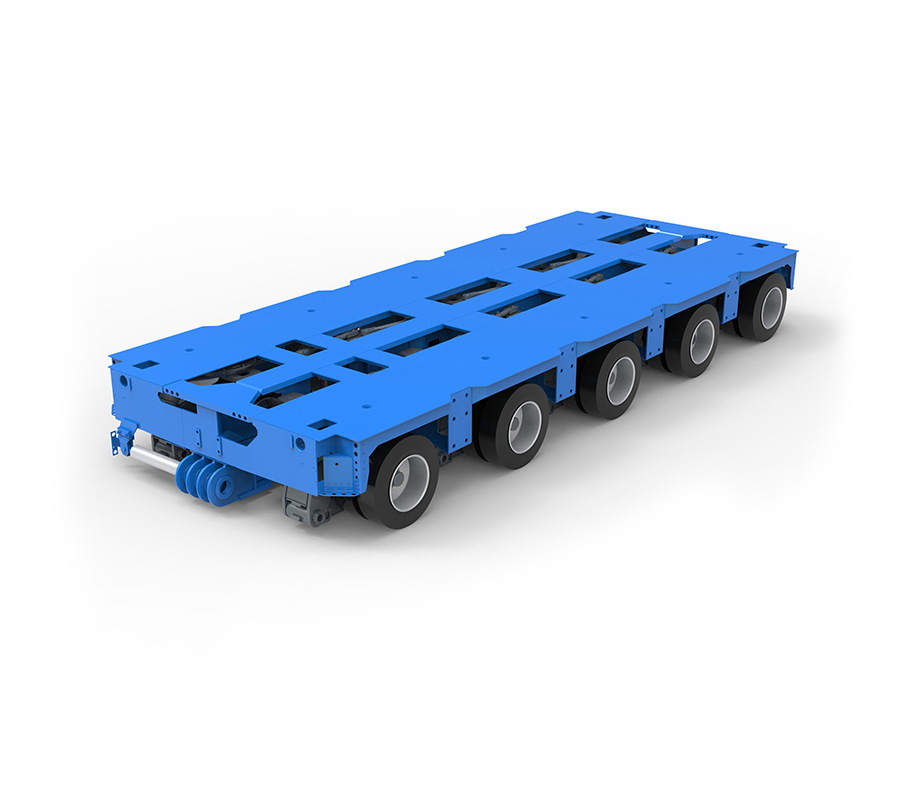

What are the main advantages of modular axle trailer design?

In the modern field of oversized and heavy equipment transportation, the Modular Axle Trailer has become an indispensable key piece of equipment. Its design concept is centered around modularity, intelligence, flexibility, and safety. Through structural innovation and system integration, it provides a solid foundation for the efficient transportation of bulk cargo, specialized equipment, and oversized components. For manufacturing companies, the technical advantages of modular trailers lie not only in their load-bearing capacity but also in their comprehensive adaptability and reliability.

Strong load-bearing capacity and flexible modular combination

The Modular Axle Trailer's greatest design advantage lies in its ability to freely combine multiple axle units to create vehicle groups of varying sizes and load capacities. Unlike traditional fixed-structure trailers, the modular design allows for flexible configuration based on the weight, length, and shape of the cargo being transported, significantly enhancing transport adaptability. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. fully utilizes hydraulic suspension and multi-axle distribution principles in its design to achieve efficient load distribution, ensuring the safety and stability of overweight cargo during transportation.

Hydraulic Suspension System Ensures Driving Stability

Hydraulic suspension is another core advantage of the Modular Axle Trailer. Through intelligent adjustment of vehicle height, the vehicle not only adapts to complex road conditions but also achieves dynamic load balance, reducing uneven load distribution during transport. The hydraulic suspension also enables the vehicle to traverse uneven roads and low obstacles, improving overall transport efficiency. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s hydraulic technology solution combines hydro-pneumatic suspension with a high-precision hydraulic control system to ensure stable driving even under heavy loads, which is particularly important for transporting high-value equipment and precision components.

Multi-axle Steering System Improves Maneuverability

When transporting extremely long and heavy objects, turning radius and road adaptability are key factors in determining transport efficiency. The Modular Axle Trailer utilizes a multi-axle coordinated steering design, enabling even vehicles hundreds of meters long to maneuver nimbly on narrow roads and at urban intersections. Hydraulic or electronic steering significantly enhances vehicle maneuverability. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. incorporated variable wheelbase and multi-axle intelligent steering systems into its product development, enabling customers to quickly adjust vehicle fleets to suit diverse transport environments, ensuring both flexibility and safety.

Highly Modular, Adaptable to Multi-Industry Needs

Whether transporting wind turbine blades, bridge steel structures, nuclear power equipment, or large construction machinery, transportation requirements often vary significantly. The modular structure of the Modular Axle Trailer allows for configurations of varying lengths, widths, and loads to meet specific needs. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. offers a variety of specialized products in its product line, including high-tech hydraulic axle semi-trailers, wind turbine equipment transporters, and construction machinery transporters, catering to diverse customer scenarios across industries such as energy, infrastructure construction, and precision instrument manufacturing.

Safety and Compliance Design

Heavy-load transport inherently carries significant safety risks, making safety a core design element of the Modular Axle Trailer. Hydraulic braking, redundant control systems, and highly reliable connections ensure safe operation even under extreme conditions. All products of Hangzhou Kotter Intelligent Manufacturing Co., Ltd. have passed China's "3C" compulsory certification and strictly adhere to domestic and international transportation regulations, ensuring that their products are not only technologically advanced but also compliant and competitive in the international market.

How does a modular axle trailer differ from a conventional lowbed trailer in terms of load capacity?

Essential Difference in Structural Load Capacity

Conventional lowbed trailers typically rely on a steel frame and a limited number of axles to support their loads. Their load capacity is constrained by the number of axles, frame strength, and suspension structure. In most cases, these trailers are suitable for transporting machinery and equipment weighing tens to over a hundred tons, but are prone to structural fatigue and uneven load distribution at higher weights.

In contrast, the Modular Axle Trailer utilizes a highly modular design. Each module incorporates a multi-axle hydraulic suspension system that can be combined through mechanical and hydraulic coupling. By freely connecting multiple modules, the load capacity can be multiplied, meeting the needs of transporting hundreds or even thousands of tons of cargo. This structural advantage makes the Modular Axle Trailer far superior to conventional lowbed trailers in heavy-load transportation.

Multi-axle distribution improves load distribution

Lowbed trailers have a limited number of axles, typically between two and five. This concentrates the load on some axles, which can easily lead to excessive ground pressure, increasing road damage and transport risks. The Modular Axle Trailer's multi-axle distribution design evenly distributes the load across a larger number of wheels and suspension systems, effectively reducing single-point loads and better adapting to varying road conditions.

During its development, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. fully utilized multi-axle linkage and hydraulic balancing principles, enabling its modular trailer to maintain stable load distribution even under heavy loads. This is particularly critical for bridge navigation and road safety during overload transport.

Advantages of Hydraulic Suspension and Dynamic Adjustment

Conventional lowbed trailers often use leaf springs or simple airbag suspension systems, which have limited adaptability when loading. The Modular Axle Trailer, on the other hand, utilizes hydraulic suspension, which, through hydraulic cylinder adjustment, not only automatically balances according to load size but also allows for flexible height adjustment, ensuring stable transport of cargo. This dynamic adjustment capability enables the Modular Axle Trailer to easily navigate complex road conditions and uphill and downhill slopes, significantly improving load reliability and transport efficiency. The hydraulic suspension system manufactured by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. combines hydro-pneumatic suspension technology with precise hydraulic control solutions, ensuring not only load-bearing performance but also enhancing safety during long-distance transport.

Load-carrying advantages brought by adaptability and scalability

Lowbed trailers are typically designed with a fixed structure and limited scalability. The modular nature of the Modular Axle Trailer allows for flexible expansion of load capacity based on mission requirements. Whether a single module can carry tens of tons or multiple modules can be combined to carry thousands of tons, the configuration can be optimized to suit the transport mission.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. boasts a comprehensive modular product line, offering customers a variety of solutions, including multi-axle hydraulic semi-trailers, wind turbine equipment transporters, and construction machinery transporters, meeting the transport needs of various weight classes across industries such as energy, infrastructure, and precision manufacturing.

Safety and regulatory advantages

When comparing load capacities, transportation safety and regulatory compliance must also be considered. Due to their limited carrying capacity, lowbed trailers often require multiple transports to complete their mission, increasing transportation costs and risks. Modular Axle Trailers, on the other hand, accomplish their mission with a single, high-load transport, reducing the number of trips and better meeting the efficiency requirements of oversized transport. Furthermore, their balanced axle load distribution makes it easier to meet road load regulations. All products from Hangzhou Kotter Intelligent Manufacturing Co., Ltd. are certified by China's "3C" (Certified Compulsory Compulsory) and strictly adhere to transportation regulations, ensuring a balance between load-bearing performance and safety.

What factors primarily determine the load-bearing capacity of a modular axle trailer?

Number of modules and assembly method

Load-bearing capacity is primarily determined by the number and assembly method of modules. Each modular unit has multiple axles and suspension systems, capable of independently carrying a certain weight. When multiple modules are connected through mechanical and hydraulic interfaces, the load capacity can be expanded linearly or even exponentially. The rationality of the assembly method directly determines the vehicle's total load-bearing capacity and operational stability.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. offers flexible assembly solutions in its modular design. Customers can flexibly combine different numbers and arrangements of modules based on the transport mission, ensuring both load requirements and road conditions.

Number and distribution of axles

The number of axles is a key indicator of load-bearing capacity. The more axles a vehicle has, the more load points it can distribute, reducing the stress on each axle and improving overall load-bearing capacity. Furthermore, the rationality of axle distribution affects load balance and vehicle stability. If the distribution is not rational, even with a sufficient number of axles, there is still a risk of localized excessive stress. To address this issue, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. utilizes multi-axle linkage steering and balanced load distribution technology to ensure that each axle effectively shares weight, achieving improved load-bearing performance and greater road adaptability.

Suspension System and Hydraulic Technology

Load-bearing capacity is not just about static support; it also includes stability during dynamic transport. The hydraulic suspension system adjusts load distribution in real time to ensure even force across all wheels, thereby preventing structural damage caused by overloading at a single point. Furthermore, the hydraulic suspension can adjust its height to adapt to complex terrain, making heavy-load transport safer and more efficient.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. integrates hydraulic and hydro-pneumatic suspension technologies in its products, ensuring the vehicle remains stable even under heavy loads. This makes it particularly suitable for applications requiring extremely high stability, such as wind power plants, bridge construction, and large equipment transport.

Frame and Connection Structure Strength

The strength of the frame and connection structure is the foundation of load-bearing capacity. High-strength steel, optimized welding processes, and scientific mechanical structural design effectively prevent bending or fatigue damage under extreme loads. The connection system between modules is equally critical, requiring sufficient stability and safety under high loads.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. utilizes an optimized mechanical distribution structure in its frame design, coupled with precision manufacturing processes and reliable connection locks, to ensure the vehicle maintains overall rigidity even under high loads.

Traction System and Power Gooseneck Configuration

For heavy-load transport, the load-bearing capacity of the frame and modules alone is not enough to guarantee overall performance. The traction system, particularly the power gooseneck configuration, plays a crucial role in load-bearing capacity. It not only requires sufficient traction but also forms an efficient mechanical coupling with the modular vehicle assembly to ensure that overweight cargo remains stable during starting, braking, and cornering.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has extensive experience in power gooseneck technology and can provide customers with highly customized power transmission solutions, enhancing the vehicle's overall load-bearing and operational capabilities.

Steering System and Operational Controls

Load-bearing capacity is also affected by the steering system design. Insufficient steering angles or imprecise control during cornering can easily lead to localized overloading, compromising overall load-carrying capacity. Multi-axle coordinated steering or electronically controlled steering systems ensure the vehicle maintains maneuverability even under heavy loads, improving safety and stability during transportation.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. combines multi-axle steering with intelligent control, enabling modular trailers to maintain balanced load distribution and efficient load-carrying even in complex road conditions.

How do modular axle trailers adapt to different road conditions?

Urban Roads and Narrow Roads: Multi-Axle Steering and Variable Wheelbase

Vehicle flexibility is crucial on urban roads or on narrow construction sites. Conventional lowbed trailers, with their fixed wheelbase and limited steering options, often struggle to transport overloaded goods in complex road networks. In contrast, the modular axle trailer, with its multi-axle coordinated steering system, enables wide-angle turns, allowing even long vehicle groups to maneuver through narrow spaces. Furthermore, the variable wheelbase design allows for adjustments based on road width and turning radius, effectively improving vehicle maneuverability. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. combined multi-axle steering with intelligent control technology during its development process, giving its modular trailers greater adaptability and operational safety in urban environments.

Highway and Long-Distance Transport: Modular Combinations and Powered Goosenecks

In highway and long-distance transport scenarios, transport efficiency and driving stability are paramount. In these situations, modular axle trailers typically utilize a modular linear combination to ensure vehicle stability and wind resistance. Furthermore, the appropriate configuration of a powered gooseneck ensures more efficient traction distribution, ensuring that heavy loads remain stable during long transport periods.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. offers a variety of powered gooseneck solutions, which can be flexibly configured based on cargo weight and road conditions, enabling customers to achieve optimal load carrying and traction efficiency for both high-speed and long-distance transport.

Mountain Roads and Complex Slopes: Hydraulic Suspension and Height Adjustment

Mountainous roads often feature steep slopes, numerous curves, and uneven surfaces, placing higher demands on the stability and climbing ability of transport vehicles. The Modular Axle Trailer utilizes a hydraulic suspension system that dynamically adjusts the load on each axle to ensure the vehicle maintains balance on uneven surfaces. Furthermore, suspension height adjustment reduces the risk of chassis scraping when navigating slopes or small obstacles.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has extensive experience in the research and development of hydraulic and hydro-pneumatic suspensions. Its products ensure stable operation under heavy loads, making them particularly suitable for transport tasks in mining areas, mountainous areas, or large-scale infrastructure construction sites.

Soft Terrain and Construction Sites: Multi-Axle Distribution and Low Ground Pressure

Vehicles can easily get stuck or slip on sandy terrain, soft soil, or unpaved construction sites. In such scenarios, the Modular Axle Trailer reduces the load on each axle by increasing the number and density of axles, thereby reducing the ground pressure and improving the vehicle's maneuverability on soft surfaces. Some modules can also feature wider tires or dual tires to further reduce ground pressure. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s modular products support a variety of axle combinations, enabling flexible configuration for different working conditions and effectively addressing the issue of vehicles getting stuck during construction site transportation.

Bridges and Sensitive Road Sections: Load Balancing and Intelligent Monitoring

When crossing bridges or sections with load restrictions, vehicles must strictly control single-axle loads and overall weight distribution. The Modular Axle Trailer utilizes a hydraulic balancing system to evenly distribute the load, preventing local overloading. Furthermore, modern modular trailers can also incorporate intelligent monitoring systems, providing real-time feedback on axle loads and suspension status, ensuring safe passage through sensitive road sections.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. actively incorporates digital control and remote monitoring technologies into its products, enabling users to monitor vehicle operating status in real time during transportation, improving transportation safety and compliance.

English

English  中文简体

中文简体